Cold storage refrigeration aluminum row

Key words:

Classification:

Description

Energy-saving aluminum tube (aluminum alloy fin tube evaporator) for the fin and tube integrated die-casting molding structure, mainly used for low-temperature cold storage refrigeration system in all kinds of food freezing, cold storage in the ideal evaporator. Aluminum alloy quick-frozen shelf tube is used to replace the seamless steel tube shelf tube of a new generation of products are widely used in the segmentation of meat, aquatic products, poultry, pasta, conditioning food and some fruits and vegetables food rapid freezing.

Aluminum tube features:

1. Good thermal conductivity Compared with the traditional steel row direct-cooled evaporator, aluminum alloy has excellent thermal conductivity. Under the same temperature conditions, the thermal conductivity is 210W(m2.°C), and the steel is only 46W(m2.°C).

2, sheet type: mainly divided into two fins and multi fin type.

3, the heat exchange area per unit length increases, the projection area of aluminum row and evaporation area ratio can be 1:3 or 1:4, aluminum row can be fully installed on the top surface of the cold storage, so that the heat exchange capacity per unit area is more energy-saving and efficient than the use of steel row.

4, light weight and easy installation, the weight of each meter of aluminum row is only about 1/5 of the steel row, in the construction of cold storage greatly reduced the top load and a variety of hoisting auxiliary materials, improve the installation efficiency, reduce the installation cost.

5, the amount of refrigerant is small, the aluminum row uses the outer fin structure, the amount of refrigerant injection will be greatly reduced, saving refrigerant costs.

6. Less dry consumption of food: the aluminum row is hoisted on the top of the cold storage to form direct cooling natural convection, so as to minimize the dry consumption of the cooled articles.

7. High pressure resistance of the row tube: the one-time die-casting structure of the aluminum fin and the tube, the strength of the fin and the aluminum tube are strengthened each other, and the pressure resistance of the aluminum tube is also greatly improved.

8. The inner wall of the pipeline is smooth, and after anti-oxidation treatment, the system runs smoothly and clean.

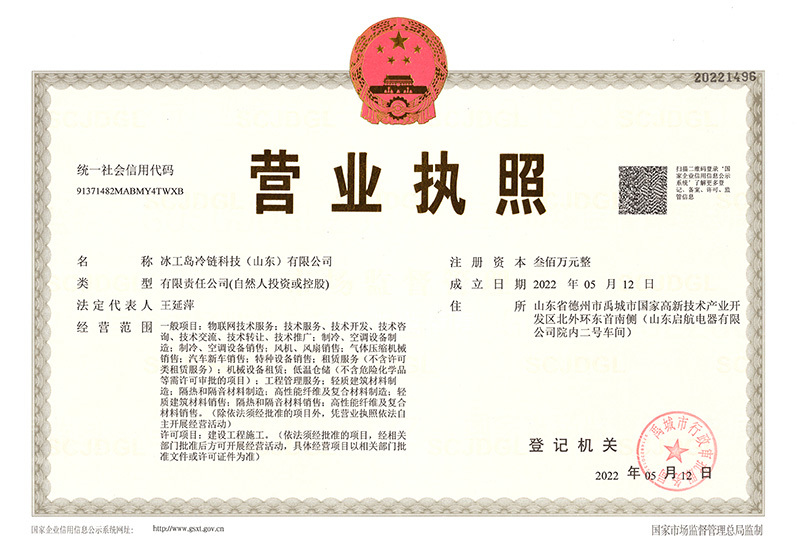

BINGGONGDAO Cold Chain Technology (Shandong) Co., Ltd.

Binggong Island Cold Chain Technology (Shandong) Co., Ltd. is located in the national high-tech industrial development zone on the Bohai Rim Economic Circle-Dezhou High-tech Industrial Development Zone. The company is a group member of Shandong Refrigeration Society, and has cooperated with many well-known colleges and universities in the country, and has obtained a number of technical application patents and high-tech enterprise certificates. The company holds the national refrigeration equipment industrial product production license, and passed the international quality management system certification, as well as electrical products 3c certification, environmental system certification.

- Product Description

-

- Commodity name: Cold storage refrigeration aluminum row

Energy-saving aluminum tube (aluminum alloy fin tube evaporator) for the fin and tube integrated die-casting molding structure, mainly used for low-temperature cold storage refrigeration system in all kinds of food freezing, cold storage in the ideal evaporator. Aluminum alloy quick-frozen shelf tube is used to replace the seamless steel tube shelf tube of a new generation of products are widely used in the segmentation of meat, aquatic products, poultry, pasta, conditioning food and some fruits and vegetables food rapid freezing.

Energy-saving aluminum tube (aluminum alloy fin tube evaporator) for the fin and tube integrated die-casting molding structure, mainly used for low-temperature cold storage refrigeration system in all kinds of food freezing, cold storage in the ideal evaporator. Aluminum alloy quick-frozen shelf tube is used to replace the seamless steel tube shelf tube of a new generation of products are widely used in the segmentation of meat, aquatic products, poultry, pasta, conditioning food and some fruits and vegetables food rapid freezing.

Aluminum tube features:

1. Good thermal conductivity Compared with the traditional steel row direct-cooled evaporator, aluminum alloy has excellent thermal conductivity. Under the same temperature conditions, the thermal conductivity is 210W(m2.°C), and the steel is only 46W(m2.°C).

2, sheet type: mainly divided into two fins and multi fin type.

3, the heat exchange area per unit length increases, the projection area of aluminum row and evaporation area ratio can be 1:3 or 1:4, aluminum row can be fully installed on the top surface of the cold storage, so that the heat exchange capacity per unit area is more energy-saving and efficient than the use of steel row.

4, light weight and easy installation, the weight of each meter of aluminum row is only about 1/5 of the steel row, in the construction of cold storage greatly reduced the top load and a variety of hoisting auxiliary materials, improve the installation efficiency, reduce the installation cost.

5, the amount of refrigerant is small, the aluminum row uses the outer fin structure, the amount of refrigerant injection will be greatly reduced, saving refrigerant costs.

6. Less dry consumption of food: the aluminum row is hoisted on the top of the cold storage to form direct cooling natural convection, so as to minimize the dry consumption of the cooled articles.

7. High pressure resistance of the row tube: the one-time die-casting structure of the aluminum fin and the tube, the strength of the fin and the aluminum tube are strengthened each other, and the pressure resistance of the aluminum tube is also greatly improved.

8. The inner wall of the pipeline is smooth, and after anti-oxidation treatment, the system runs smoothly and clean.

Our honor

Our Case

If you are interested in this product, please fill in the following information and submit it to us, we will arrange experts to contact you as soon as possible!

Related Products

Related Products